Rod Mill

Rod Mill

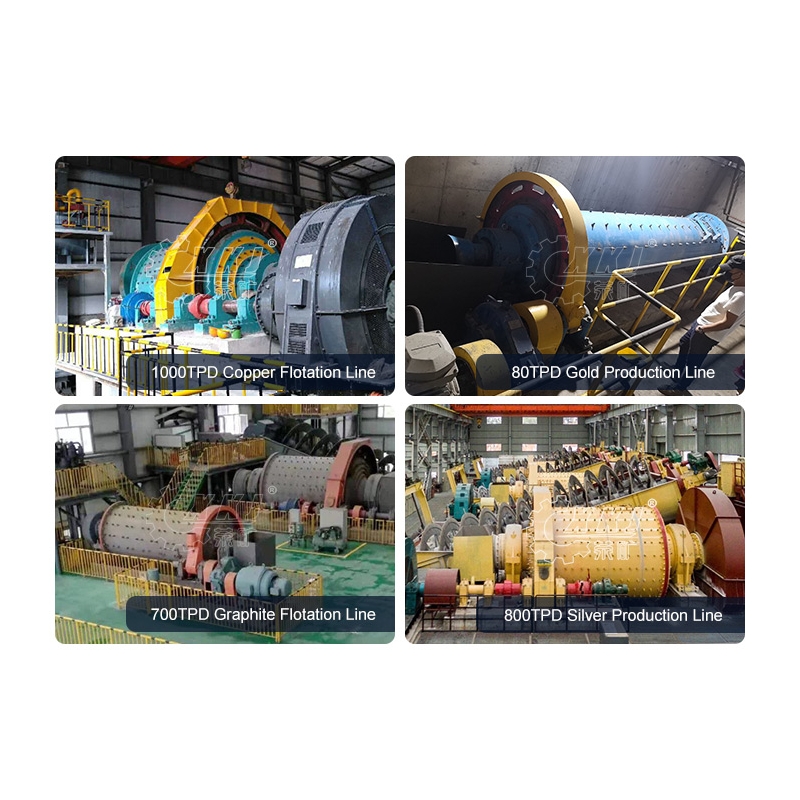

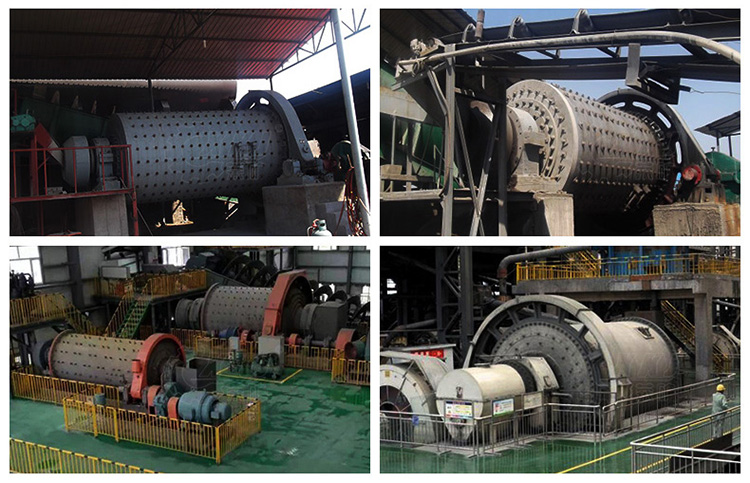

Ball mill case site

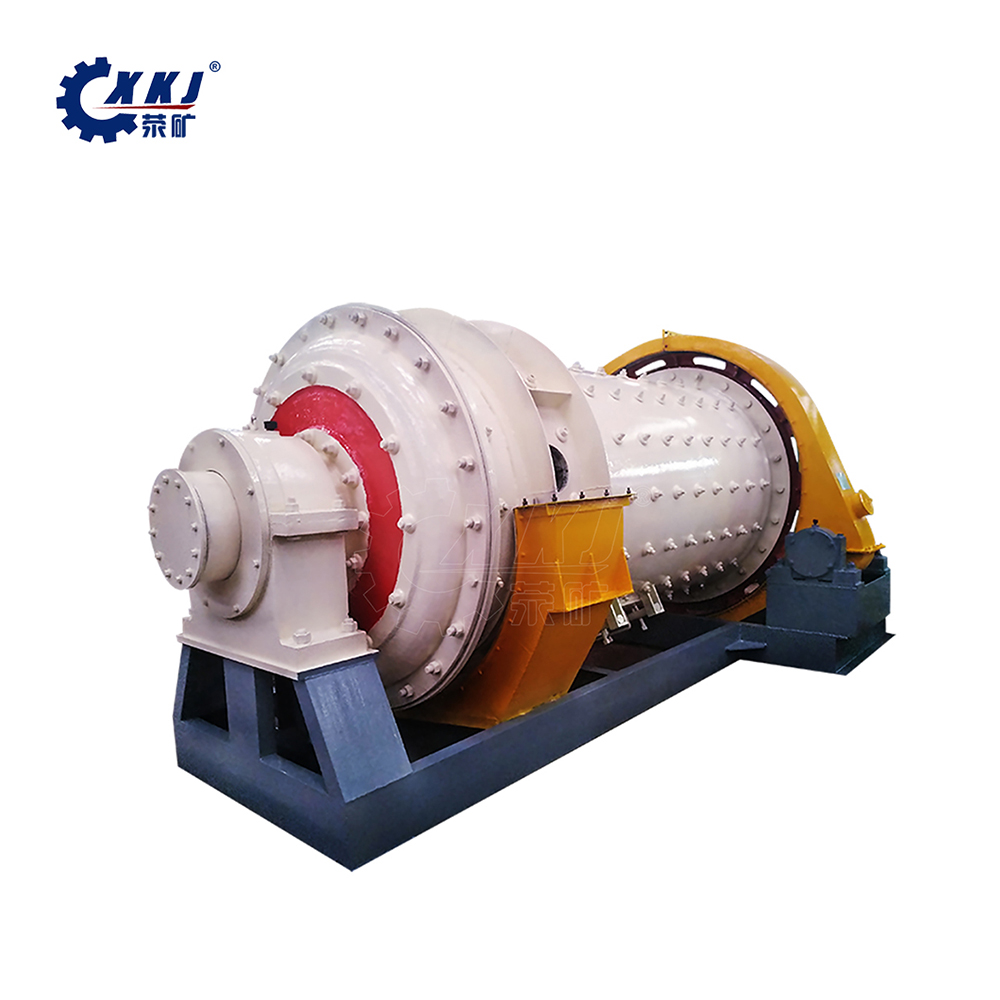

Introduction of rod mill

Rod mill or grinding rod mill can be widely applied in some fields such as refractory, chemical industry, metallurgy, glass and some other industries that have the higher requirement on the uniformity of the finished product.

Rod mill consists barrel, feeding part, discharging part, bearing part and lubrication system. Rod mill has many advantages such as high yield and uniform discharging size, which is suitable for the different hardness of ores. Rod mill has dry and wet types to be chosen, customers can choose the appropriate type according to their actual conditions.

Rod mill is widely applied in metal and nonmetal mine, water conservancy, glass and construction materials industries, mainly suitable for grinding various ores and rocks and artificial sand-making.

Feeding size: 25-50mm

Production: 3–120 t/h

Application: Cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal processing and glass ceramics and other production industries.

Processible Materials: Quartz stone, iron ore, copper ore, gold ore, cement clinker, pyrrhotite, hematite, limonite, construction waste and so on.

Features of rod mill:

1. It can save 15% of power, the granularity of product is uniform.

2. Large discharge opening, high capacity.

3. Discharging particle more uniform, suited for different ores.

4. Easy and safe operation, stable performance 5. Low invest, high return.

Technical Parameters Of Rod Mill

| Model | specification(mm) | Cylinder RPM | Feed size (mm) | Discharge size (mm) | Capacity (t/h) | Power (kw) | Weight(t) | |

| Diameter | Length | |||||||

| MB0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

| MB0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| MB1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| MB1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| MB1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| MB2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| MB2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| MB2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| MB2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| MB2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| MB3245 | 3200 | 4500 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |

Contact Us

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China