Raymond Mill

Raymond mill

This machine adopts the advanced structure of similar products at home and abroad, and is designed and updated on the basis of Raymond mills in the same industry. This equipment is more efficient than ball mills, consumes less power, occupies a smaller area, and requires less one-time investment.

Production capacity:10-320t/d

Production granularity:80-1000 mesh

Feed particle size:≤30mm

Application areas:Calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, non-metallic ore pulverizing, pulverized coal preparation, etc.

Equipment introduction of Raymond mill

R-type Raymond mill is widely used in barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, Highly fine powder processing of more than 280 kinds of materials in mineral, chemical, construction and other industries with a Mohs hardness of not more than 9.3 and a humidity of less than 6% such as glass and insulation materials. The final product particle size is in the range of 80-325 mesh. Adjust as desired.

This machine adopts the advanced structure of similar products at home and abroad, and is designed and updated on the basis of Raymond mills in the same industry. This equipment is more efficient than ball mills, consumes less power, occupies a smaller area, and requires less one-time investment.

Outstanding advantages of Raymond mill

1.Smooth rotation and reliable operation

The main transmission device of Raymond mill adopts sealed gear box and pulley, which ensures smooth transmission and reliable operation.

2.High screening rate

Compared with other grinding equipment, the screening rate is high, and the screening rate is as high as 99%, which is generally not achieved by other grinding equipment.

3.Consumable parts have long service life

The wearing parts are made of high manganese steel with long service life, and the motors are all national standard products.

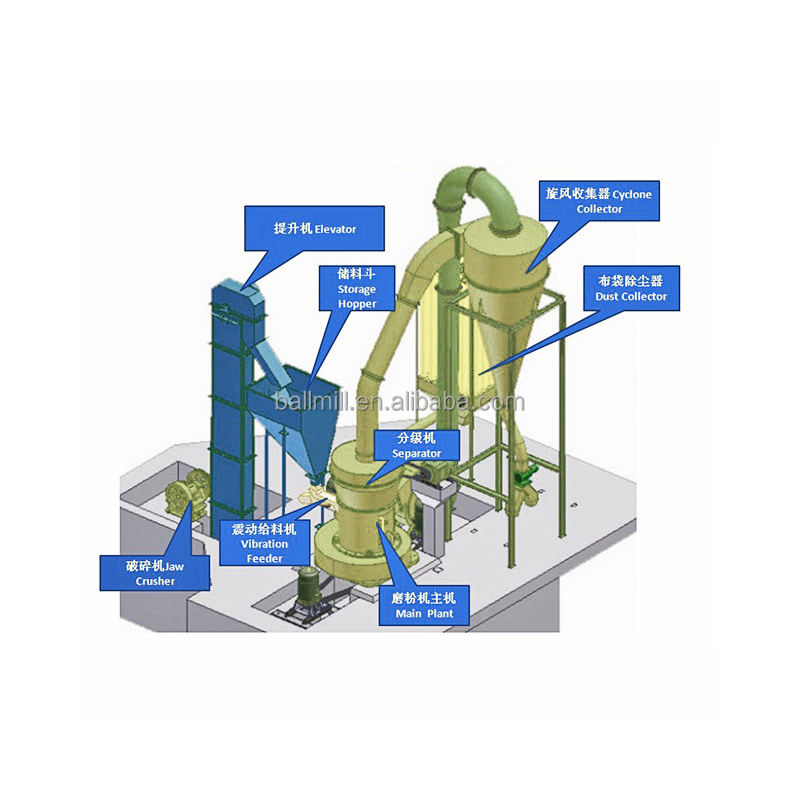

working principle of Raymond mill

The structure of the machine mainly consists of a host machine, an analyzer, a fan, a finished cyclone separator, a powder cyclone separator and an air duct. Among them, the main machine consists of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, and a cover.

After the material is ground, the fan will blow the wind into the main casing, blowing up the powder, which will be sorted by the analyzer placed above the grinding chamber. Materials that are too fine and too coarse will fall into the grinding chamber for regrinding, and those with a fineness that meets the specifications will It enters the cyclone collector with the wind flow, and is discharged through the powder outlet after collection, which is the finished product. The air flow returns to the fan from the return duct at the upper end of the large cyclone collector. The air path is circular and flows under negative pressure. The increased air volume in the circulating air path is discharged through the exhaust pipe between the fan and the host machine and enters the small cyclone collection device for purification.

Technical Parameters of Raymond mill

Model | 3R2115 | 3R2615 | 3R2715 | 3R3016 | 4R3216 | ||

Milling Roller | Number | 3 | 3 | 3 | 3 | 4 | |

Diameter (mm) | 210 | 260 | 270 | 300 | 320 | ||

Height (mm) | 150 | 150 | 150 | 160 | 160 | ||

Milling Ring | Inner Diameter (mm) | 630 | 780 | 830 | 880 | 970 | |

Height (mm) | 150 | 150 | 150 | 160 | 160 | ||

Max. Feed Size (mm) | 15 | 15 | 15 | 20 | 25 | ||

Finished Product Size (mm) | 0.044~0.165 | 0.044~0.165 | 0.044~0.165 | 0.044~0.165 | 0.044~0.165 | ||

Main Motor Power (kW) | 15 | 18.5 | 22 | 30 | 37 | ||

Finish Product | 0.125 | Output(t/h) | 1.2~1.8 | 1.8~2.5 | 2.3~2.8 | 0.6~1.2 | 3.2~4.5 |

0.075 | 0.6~1.2 | 1.2~1.8 | 1.8~2.3 | ||||

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China