Ore Grinding Ball Mill

Gold Ore Ball Mill

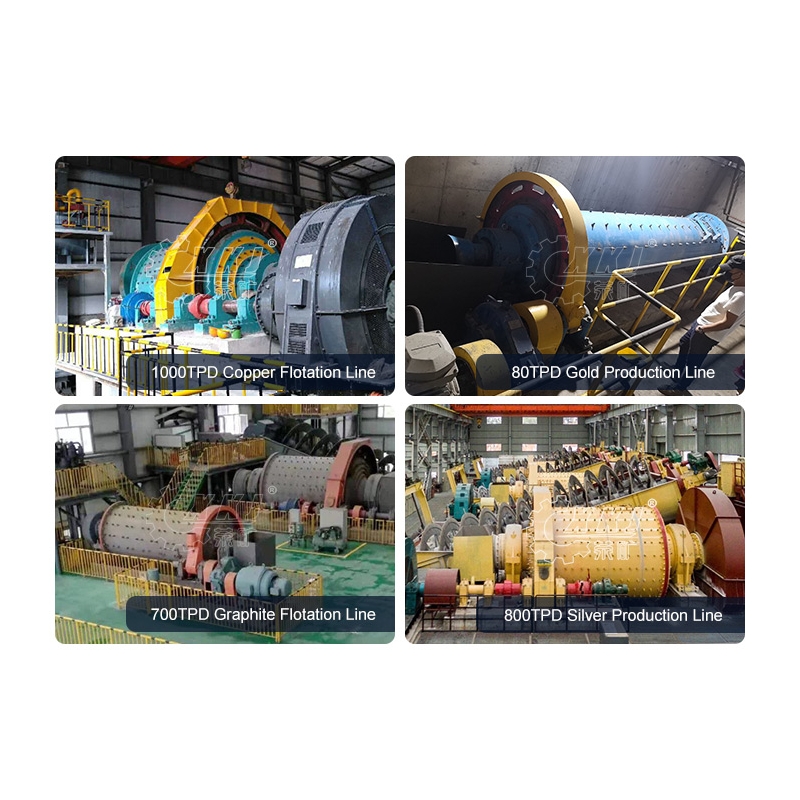

Case Site Of Gold Ore Ball Mill

We assigned the best engineers to our customer site, make sure all the machines run perfectly.

Ore Ball Mill Description

Ball mill is commonly seen in beneficiation production line. It is the key material grinding equipment after crushing. It iswidely used for mineral grinding such as cement,lime, quartz, slag, iron ore, copper ore, gold ore, bauxite, calcite, barite,gypsum, etc. in mining, quarry, chemical industry and other industries. Ball mill can be used for wet and dry grinding.

Ball Mill Features:

1. is an efficient tool for grinding many materials into fine powder.

2. The ball mill is used to grind many kinds of mine and other materials, or to select the mine

3. Ball mill is widely used in building material, and chemical industry.

4. There are two ways of grinding: the dry way and the wet way.

5. Ball mill can be divided into tabular type and flowing type according to differentexpelling mine

6. To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the

product into fine powder over a period of several hours.

8. The longer the ball mill runs, the finer the powder will be.

9. Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

10. Our ball mills have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals.

11. Complet ely enclosed welded design in high-grade steel.

- Direct drive via bearing journal with top-mounted gearbox.

Motor connected to gearbox via a V-belt drive.

- Product discharge via slots located around the periphery of the drum.

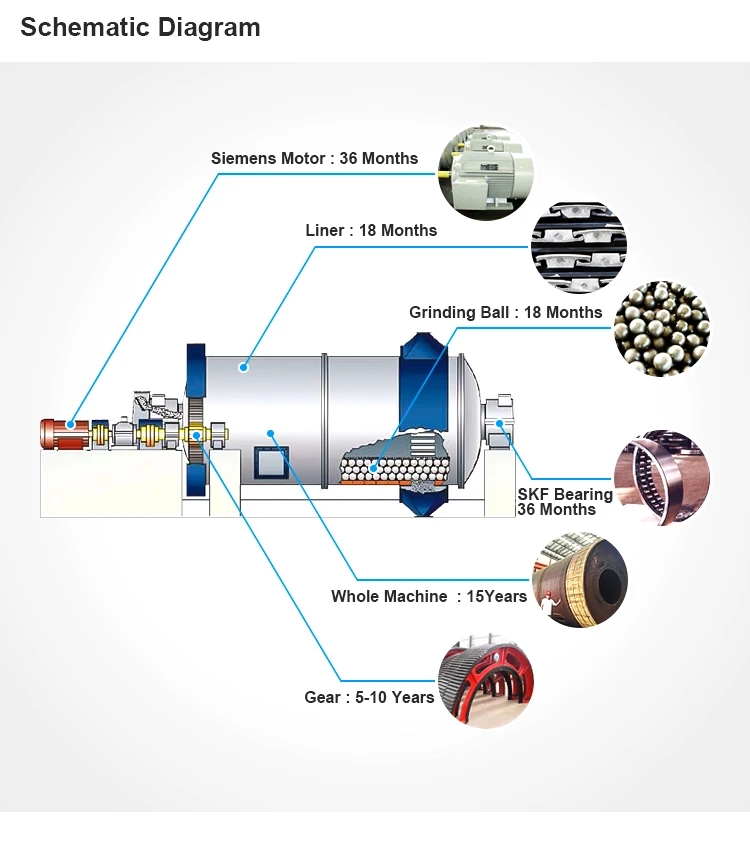

Schematic Diagram Of Gold Ore Ball Mill

Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Ore Ball Mill Paramaters

Note: The capacity is depend on the hardness and output size of the material that you want to processing, so this capacity data is only for your reference, please kindly confirm us:

(1).what kind of material do you want to grinding ?

(2).what's the max size of your material ?

(3).what's your requirement of output size ?

(4).what's your requirement of capacity?

Contact US

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China