Ceramic Ball Mill

Ceramic Ball Mill

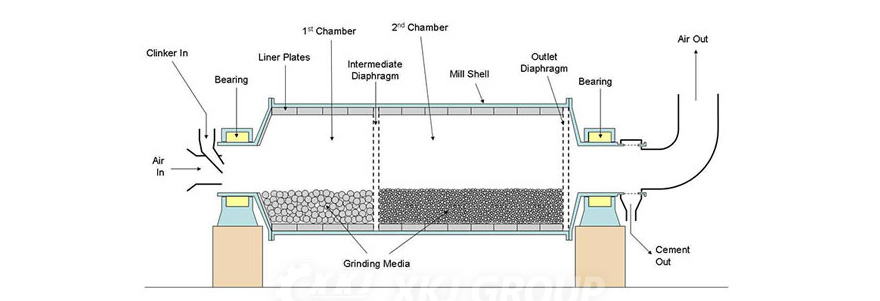

Ceramic ball mill is a ball mill whose lining plate is made of ceramic. It has a small capacity and is generally suitable for small batch production in the product trial production stage. It is a domestic mineral concentrator.

Another new type of energy-saving ball milling equipment developed by mechanical experts based on the latest domestic ball milling technology. It not only improves production capacity and crushing efficiency, but also expands the scope of application, from limestone to basalt, from stone production to various ore crushing. It They can provide unparalleled crushing performance in various medium crushing, fine crushing and ultra-fine crushing operations. It is the latest generation product that replaces spring cone crushers and updates general hydraulic cone crushers in today's mining and construction industry. It is the most ideal equipment for large stone plants and mining crushing. The structure of ceramic ball mills can be divided into integral and independent types. Compared with other ball mills, ceramic ball mills save energy and time, are easy to operate, and have more stable and reliable performance.

Introduction of Ceramic ball mill

Ceramic ball mill is mainly applied to the powder processing of mineral products in the industries of metallurgy, construction materials, chemical, and mining, etc. It can grind various ores and other materials with dry type and wet type.

Features of Ceramic ball mill:

1. Energy-saving, new structure, high capacity.

2. Stable performance, easy operation.

3. Simple structure and split installation.

4. Multi-class seals.

5. Low invest, high return

Advantage Of Ceramic ball mill

Ceramic ball mill reduces replacement frequency of easily damaged parts at the most extent. Lining plates ,steel balls are made of high chrome steel,which is very wear-resisting and durable, brings a lot of advantages for ball mill’s maintenance and working.

Loading: 0.05-15 tons / times

Production: 0.2– 120 t/h

Application: Cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal processing and glass ceramics and other production industries.

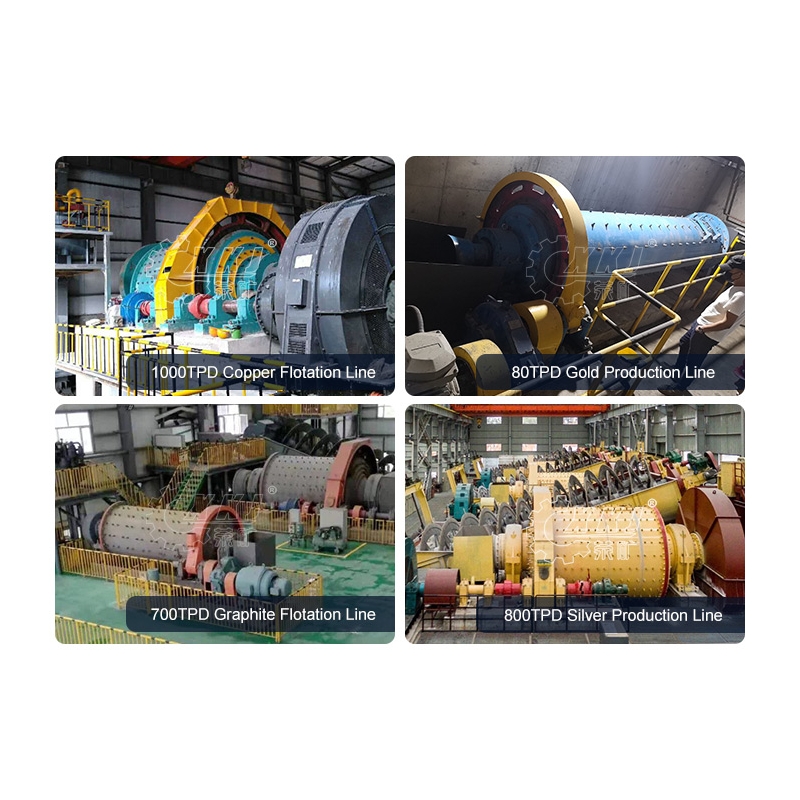

Processible Materials: Copper ore, pyrrhotite, hematite, limonite, molybdenum ore, potassium feldspar and so on.

Technical of Ceramic ball mill

| model | Loading capacity (tons/time) | Rotating speed of cylinder (rev/min) | Reference power(kw) | Lining board material |

| 600×700 | 0.05 | 50 | 2.2 | Ceramic, silica, rubber, metal (supporting power will vary depending on the material of the lining board and the grinding material) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

Contact Us

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China