Ore Grinding Ball Mill

White ash ball mill

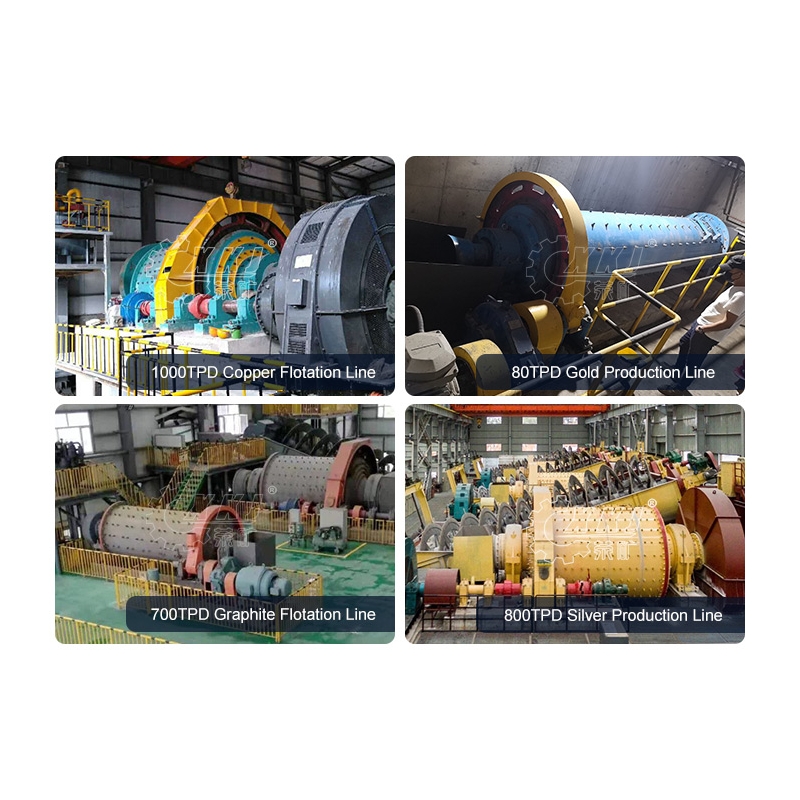

The white -gray ball mill is mainly suitable for processing the processing of various non -easy -to -burn -out ore products with various non -burn -burning and explosive ore products below the Mo's hardness. Metallurgical, building materials, chemicals, mines, highway construction, water conservancy and hydropower industries have been widely used.

Milk size: 0.074-0.9mm

Cold volume: 1.2-330t

Scope of application: white ash, limestone, iron ore, calcium carbonate, etc., are widely used in metallurgical, mine, building materials, cement and other fields.

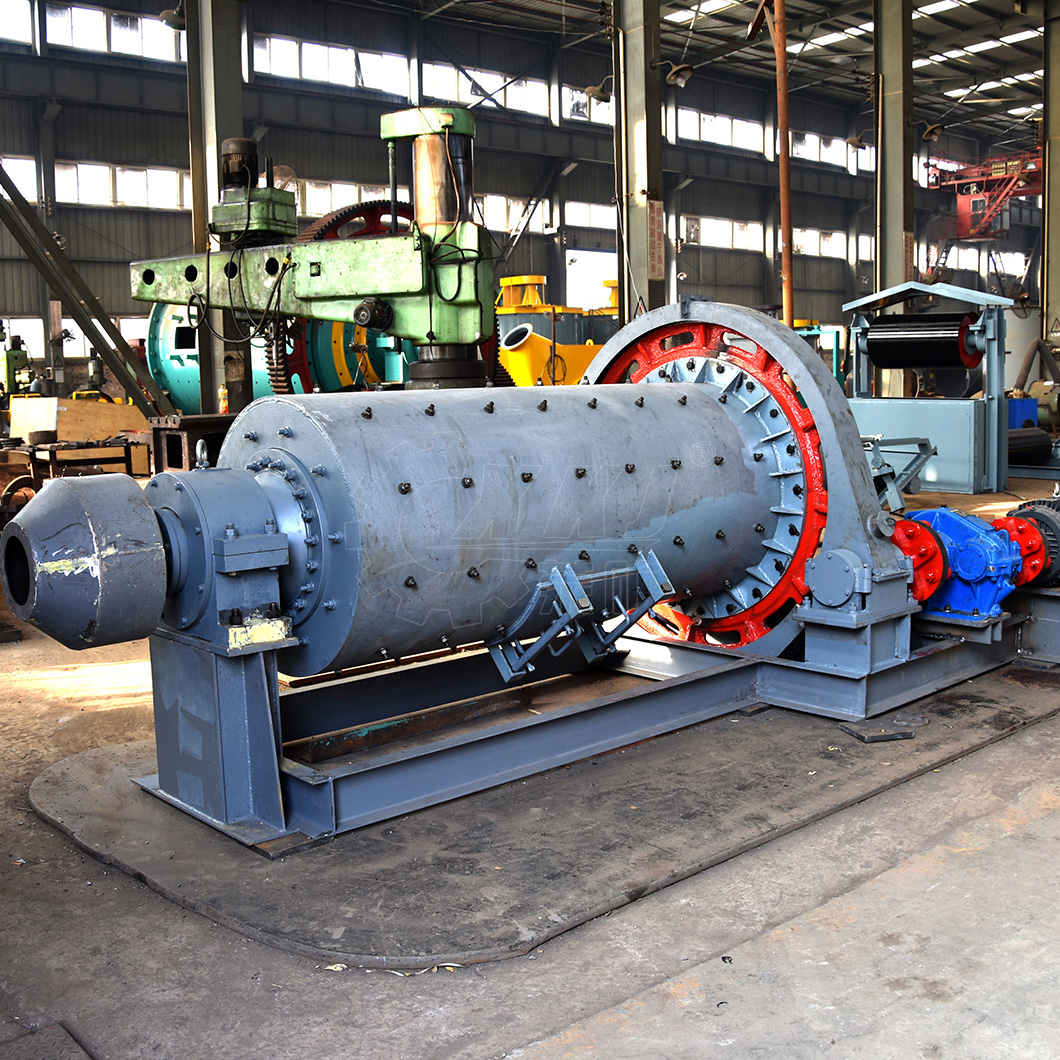

Ball mill structure:

The white gray ball mill is composed of the main part of the material department, the raw department, the return department, the reducer, the reducer, the small transmission gear, the motor, the electronic control.

1. The tube: the coal mill and milling machine includes a cylinder. The tube is inlaid in the lining made of wear -resistant materials. , Triangle belt, etc.

2. Main bearing seat: The main bearing seat adopts a sealing structure. The bearing lining and the bearing seat are in contact with the drum -shaped surface, which can automatically adjust the heart. Each main bearing is equipped with two platinum thermocouples. , Automatic stop.

3. Transmission parts: The transmission parts of the device are mainly the main electromotive motor to drive the reducer, the reducer drives the small gear, the small gear drives the large gear, and the large gear drives the tube to rotate; Replaced the conventional Bazhi Lubricon bearing, which is easier and more reliable.

4. Line plate: The lining board of the coal mill has many characteristics. Compared with other forming processes, it is not limited by the weight, size, and shape of the rough of the coal ball mill. And the repair of the lining plate is very convenient. When using the lining plate, it is often necessary to do a simple inspection of the lining plate.

The white ash ball mill produced by Henan Xingmine Machinery adopts automatic aligning double row centripetal spherical roller bearing, which has low running resistance and remarkable energy saving effect. In the cylinder part, a conical cylinder is added to the discharging end of the original cylinder, which not only increases the effective volume of the mill, but also makes the medium distribution in the cylinder more reasonable.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China