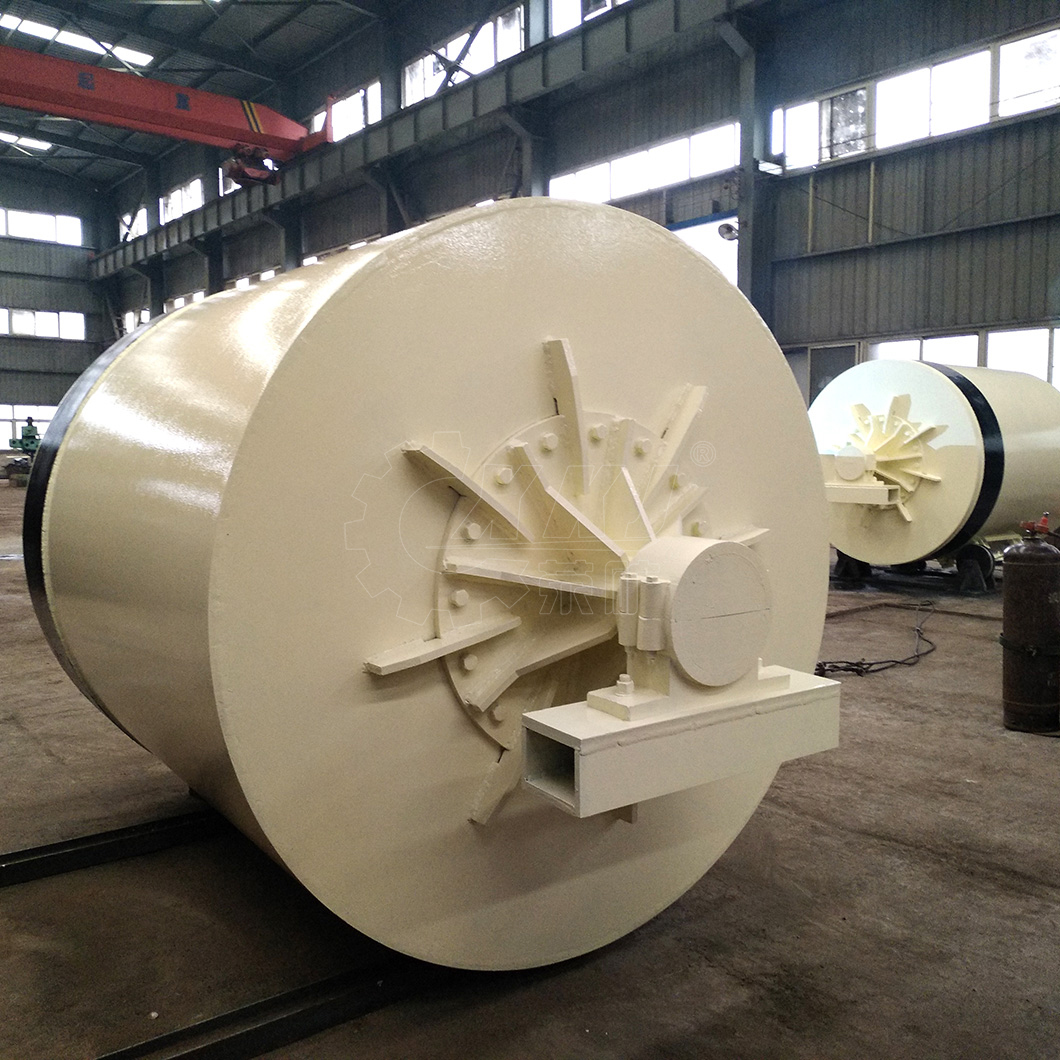

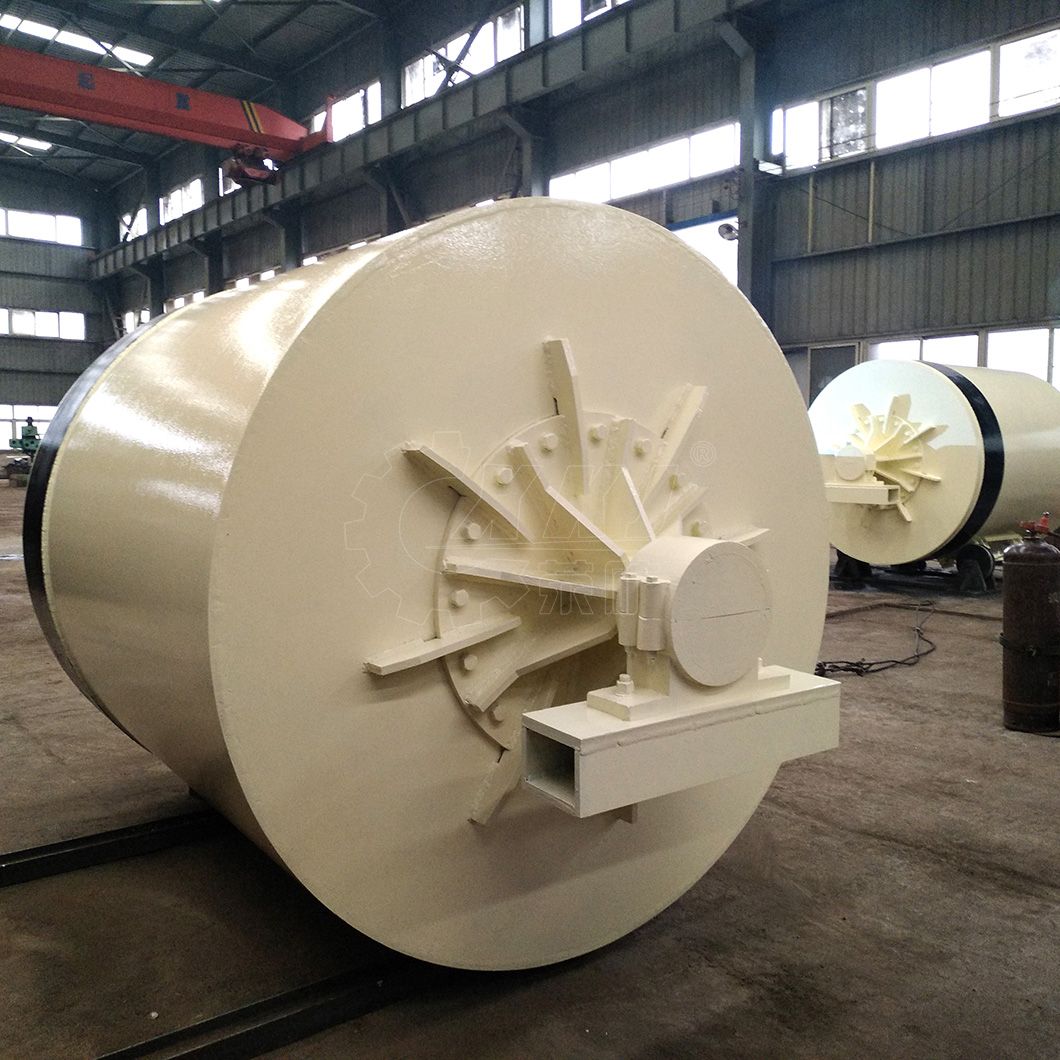

Batch Ball Mill

Batch Ball Mill

The grinding operation of the ball mill is carried out in simplified form. When the cylinder rotates, it is taken up and raised to a certain height. Due to the gravity of the steel ball itself, it finally falls along a certain track. The steel ball in the area is subjected to two forces: one is the force applied to the steel ball from the tangential direction during rotation; the other is the force symmetrical to the diameter of the steel ball but opposite to the above force. The occurrence is caused by the downward sliding of the steel ball due to its own weight. The above two forces will form a pair of force couples for the steel balls. Because the steel balls are squeezed between the cylinder and the adjacent steel balls, the force couple will cause different friction forces between the steel balls. When the ball revolves with the axis of the cylinder, it falls from the top to the bottom in the area, and then it has a strong impact on the ore in the cylinder in the area, breaking the ore. Yes, the ore in the barrel of the ball mill is mainly crushed by the action of the peeling force, impact force and squeezing force.

Working principle: The intermittent ball mill is a horizontal cylindrical rotating device with outer gear transmission, two warehouses, and a grid-type energy-saving ball mill. The material enters the first bin of the mill uniformly through the feeding device through the feeding hollow shaft spirally. The bin has a step liner or a corrugated liner with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height. After falling, it will have a heavy blow and grinding effect on the material. After the material reaches the rough grinding in the first warehouse, it enters the second warehouse through the single-layer partition board. The warehouse is lined with flat liners and steel balls to further grind the materials. The powder is discharged through the unloading grate plate to complete the grinding operation.

The intermittent ball mill is

composed of feeding part, discharging part, rotating part, transmission

part (reducer, small transmission gear, motor, electric control) and

other main parts. The hollow shaft is made of cast steel, and the inner

lining is removable. The large rotary gear is processed by casting gear

hobbing. The cylinder is inlaid with a wear-resistant liner, which has

good wear resistance. The machine runs smoothly and works reliably.

Note: According to the material and the discharging method, dry ball mill and wet grid type ball mill can be selected.

The classification situation is roughly as follows:

1. According to the type of grinding and upgrading, it can be divided into:

(1) The medium of the ball mill is metal balls (steel balls or cast iron balls).

(2) The medium of rod mill is steel rod.

(3) The gravel mill uses gravel as the grinding medium.

(4) The self-mill relies on large pieces of ore as grinding medium, and sometimes a small amount of steel balls are added.

2. According to the discharging method, it can be divided into:

(1) The overflow type ore mill freely overflows the slurry through the hollow shaft neck at the discharge end.

(2) The grid type ball mill discharges the material by means of the holes on the grid plate installed at the discharge end.

(3) Peripheral discharge type ore grinding machine discharges materials through the periphery of the cylinder.

3. According to the shape of the cylinder, it can be divided into:

(1) Short barrel type ore mill L/D≤1.0—1.5 (L is the length of the mill. D is the diameter of the mill).

(2)

Long barrel type ore grinding machine, L/D≥1.5. When L/D is 5-6, it is

called a tube mill, which is divided into several chambers inside,

called a multi-chamber mill, which is generally used in the cement

industry.

(3) my country has stopped manufacturing this type of grinding mill.

Model | Shell rotation speed(r/min) | Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity | Motor power(kw) | Weight(t) |

(t/h) | |||||||

Φ900*1800 | 36-38 | 1.5 | <=20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

Φ900*3000 | 36 | 2.7 | <=20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

Φ1200*2400 | 36 | 3 | <=25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

Φ1200*3000 | 36 | 3.5 | <=25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Φ1200*4500 | 32.4 | 5 | <=25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

Φ1500*3000 | 29.7 | 7.5 | <=25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

Φ1500*4500 | 27 | 11 | <=25 | 0.074-0.4 | 3-6 | 110 | 21 |

Φ1500*5700 | 28 | 12 | <=25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

Φ1830*3000 | 25.4 | 11 | <=25 | 0.074-0.4 | 4-10 | 130 | 28 |

Φ1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

Φ1830*6400 | 24.1 | 21 | <=25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

Φ1830*7000 | 24.1 | 23 | <=25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

Φ2100*3000 | 23.7 | 15 | <=25 | 0.074-0.4 | 6.5-36 | 155 | 34 |

Φ2100*4500 | 23.7 | 24 | <=25 | 0.074-0.4 | 8-43 | 245 | 42 |

Φ2100*7000 | 23.7 | 26 | <=25 | 0.074-0.4 | 8-48 | 280 | 50 |

Φ2200*4500 | 21.5 | 27 | <=25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

Φ2200*6500 | 21.7 | 35 | <=25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

Φ2200*7000 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-28 | 380 | 54 |

Φ2200*7500 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-30 | 380 | 56 |

Φ2400*3000 | 21 | 23 | <=25 | 0.074-0.4 | 7-50 | 245 | 54 |

Φ2400*4500 | 21 | 30 | <=25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

Φ2700*4000 | 20.7 | 40 | <=25 | 0.074-0.4 | 12-80 | 400 | 94 |

Φ2700*4500 | 20.7 | 48 | <=25 | 0.074-0.4 | 12-90 | 430 | 102 |

Φ3200*4500 | 18 | 65 | <=25 | 0.074-0.4 | ----- | 800 | 137 |

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China