Ore Grinding Ball Mill

fluorite ball mill

Introduction to fluorite ball mill:

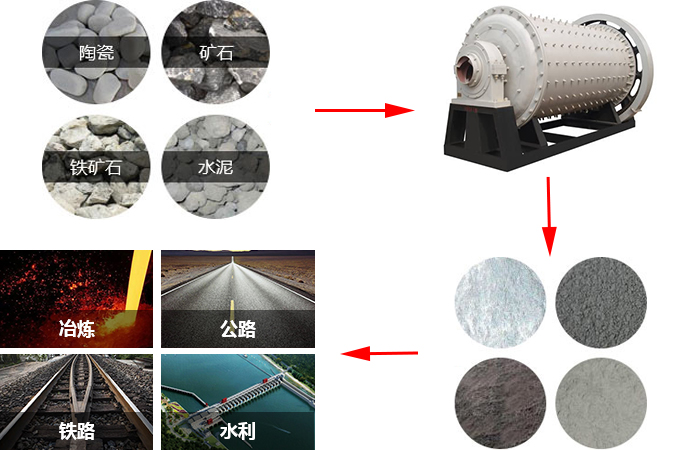

Feeding particle size: ≤20-25mm

Outgoing grinding particle size: 0.075-0.4mm

Motor power: 18.5-480kw

Production capacity: 0.65-90

The fluorite ball mill is based on years of experience in ball machine R&D and production, combined with traditional The new product developed based on the actual situation of the ball machine is very suitable for fluorite grinding. The fluorite ball grinder can control the grinding particle size during fluorite purification, achieve the fluorite purification effect, and be simple and convenient in the subsequent processing process.

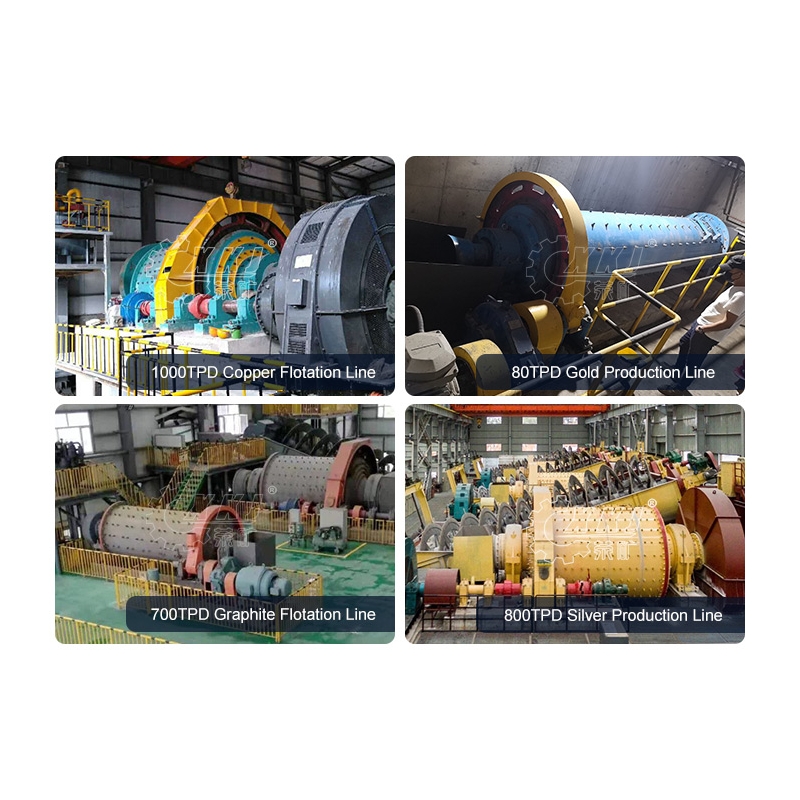

Industrial applications of fluorite ball mill:

Performance characteristics of fluorite ball mill:

1. The whole machine parts are of excellent quality

The fluorite ball mill uses variable displacement gears to improve the wear resistance and resistance of the gears, and the bending strength of the gear teeth is approximately doubled; the diameter of the hollow shaft in the rolling bearing part is thickened, extending the bearing life.

2. The equipment performance is long enough

The use of rubber linings takes advantage of the good wear resistance of rubber, so it has certain advantages in service life. Generally speaking, the service life of rubber linings is more than three times that of manganese steel linings.

3. The equipment production environment is economical enough

It plays a "soft cushion" effect on the fluorite ball mill cylinder, buffering the impact of steel balls on the cylinder, reducing noise, and changing the production environment.

4. The equipment is excellent in grinding and production

The fluorite ball mill has excellent particle size for grinding fluorite and less over-crushing, which is beneficial to subsequent processing of fluorite.

Fluorite production line:

Contact Us

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China