Company dynamics

The working principle and four major advantages of mineral processing ball mill

The working principle and four major advantages of mineral processing ball mill

The working principle and four major advantages of mineral processing ball millAfter the material is crushed by the crusher, it will enter the mineral processing ball mill for grinding, and grind it into appropriate particle size for subsequent separation and other processes. There are many grinding equipment, the common ones are mineral processing ball mill, rod mill, vertical mill, autogenous grinding mill, etc. The mineral processing ball mill has a wider range of use and is widely used in mineral processing, cement, silicate products, building materials and chemicals, Fertilizer, refractory materials, non-ferrous metal mineral processing and glass ceramics and other production industries. Why are mineral processing ball mills used more and more widely among these grinding equipment? This starts with the working principle and four major advantages of the mineral processing ball mill.

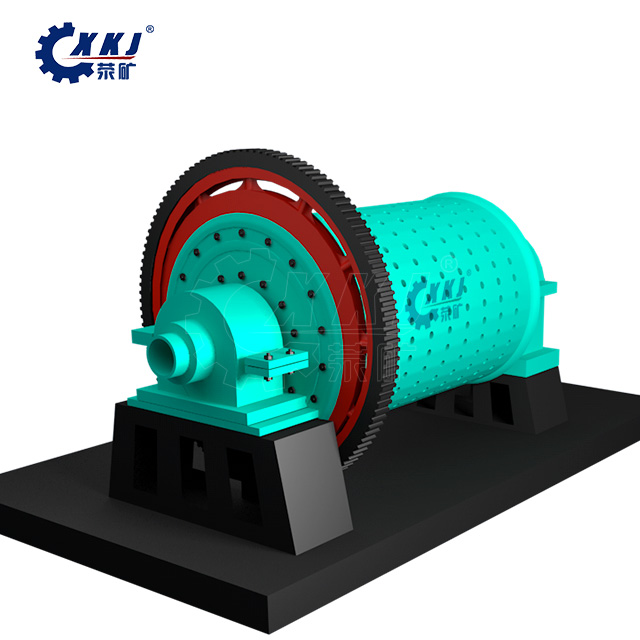

The mineral processing ball mill is a circular cylinder structure. The two ends of the cylinder are equipped with end caps with hollow journals. The journals of the end caps are supported on bearings. The mineral processing ball mill rotates through the movement of gears mounted on the cylinder. The body is equipped with grinding media such as steel balls, steel rods or gravel and the ore that needs to be crushed. The loading amount is 25%-45% of the total effective volume of the cylinder. The grinding medium and ore in the cylinder achieve a crushing effect under the action of centrifugal force and friction, and the ground finished product is discharged from the hollow journal at one end of the cylinder. The movement of the ore in the barrel of the ore dressing ball mill is achieved by continuously feeding the ore with pressure. During wet grinding, the ore is taken away by the water flow. During dry grinding, the ore is taken away by the air flow drawn out of the cylinder.

The mineral processing ball mill integrates the fuselage and chassis to change the structure of the transmission. It can be suspended on the basic plane at the same time, which greatly saves labor costs and time costs. Moreover, the spindle does not need to be replaced within 10 years, which can greatly save maintenance costs. The advantages of mineral processing ball mill equipment in production include low energy consumption, strong adaptability, high energy saving, good operating performance, and high efficiency. The following is a detailed analysis:

1. Strong versatility

It is suitable for various ore crushing production today, including the grinding of various high and low hardness metal ores, non-metallic ores, various sinter materials and other materials. Moreover, the grinding and activation can be completed at one time, and the purity of the product can be adjusted in each step. Widely used in demanding industries.

2. Structural advantages

The Yingkuang mineral processing ball mill has improved the rolling bearing, thickened the diameter of the hollow shaft, and increased the distance between the rolling bearing and the inlet and outlet spiral barrel, thereby reducing the temperature and extending the service life;

3. Zero pollution, low noise

The complete operation of the mineral processing ball mill adopts a unique "zero-emission positive pressure operation system" with good sealing, which can ensure zero pollution leakage during the production process. The fan implements sound insulation measures to make the noise of the mineral processing ball mill ≤70 decibels, and the equipment noise Low.

4. Adjustable granularity, low failure rate, and good operation

The structural design of the mineral processing ball mill adopts an automatic discharge and back-grinding system. The particle size of the incoming and outgoing materials can be adjusted, and internal lubricating parts are not required, which reduces the occurrence of equipment failures and enables the overall mineral processing ball mill to achieve more ideal operating conditions and enable long-term continuous operation.

Improvements in gear accessories include the use of variable gears to avoid undercutting and enhance the bending strength of the gears; in terms of feeders, there are two options: combined feeders and drum feeders, with simple structures and Separate installation and the correct selection of the feeder can ensure the smooth operation of the equipment, reduce the impact of inertia on the equipment, and improve efficiency; improvements in main bearings, using roller bearings instead of sliding bearings, make the equipment easy to start, saving energy and reducing consumption.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China