Product FAQ

How to use steel balls to control the "discharge particle size" of the ball mill

How to use steel balls to control the "discharge particle size" of the ball mill

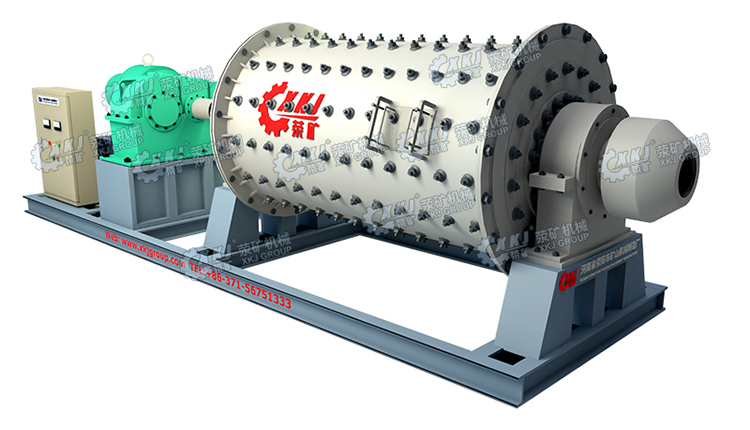

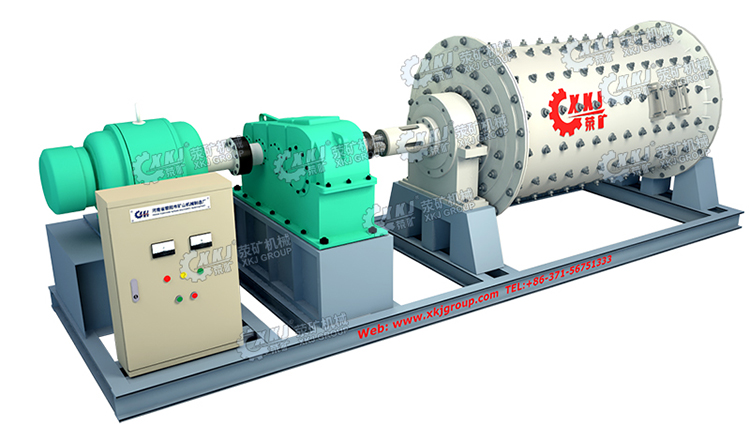

The ball mill can not only be used for grinding hard ores such as quartz stone, iron ore, copper ore, but also has good grinding effects on grindable materials, stones of various materials, and construction waste. Depending on the materials and ore discharge methods, the ball mill can There are two methods of dry ball mill and wet ball mill, which can grind fine powder with a fineness of about 800 mesh. During operation, users can choose a more suitable model for processing according to actual production needs.

Performance advantages of ball mill

1. Simplified structure and easy maintenance

The transmission device of the ball mill has been simplified, making it easier to maintain the internal reducer and gears, shortening downtime for maintenance, extending the effective service life, and increasing work efficiency.

2. Good wear resistance and extended service life

Yingkuang uses steel with good wear resistance to cast wearing parts. The hollow shaft is made of steel castings with a removable lining. The large rotary gear is processed by cast hobbing. There is a wear-resistant lining plate inside the cylinder, which has good wear resistance. Abrasion resistance, longer equipment service life.

3. Green and environmentally friendly

The ball mill is equipped with a smoke filtration system and dust removal and noise reduction equipment to control any pollution such as dust and noise within the standard range. At the same time, the main bearings are lubricated with grease to avoid heavy metal pollution and fully realize green and environmentally friendly production.

How to use steel balls to control the "discharge particle size" of the ball mill

Anyone who has used a ball mill knows that during the grinding process, the ball mill needs to continuously add steel balls to adjust the discharge particle size. So how, when, and how much steel balls should be added? To give you an example, if the required particle size of the finished product is 80 mesh, and the discharged particle size of the test machine is 70 mesh, then it means that the number of small balls is not enough, and the number of small balls needs to be increased. Otherwise, the discharged particle size is smaller than the required particle size of the finished product, it may be The large or medium balls are worn and become smaller during the grinding process. It is necessary to reduce the number of small balls and increase the number of large balls.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China