Product FAQ

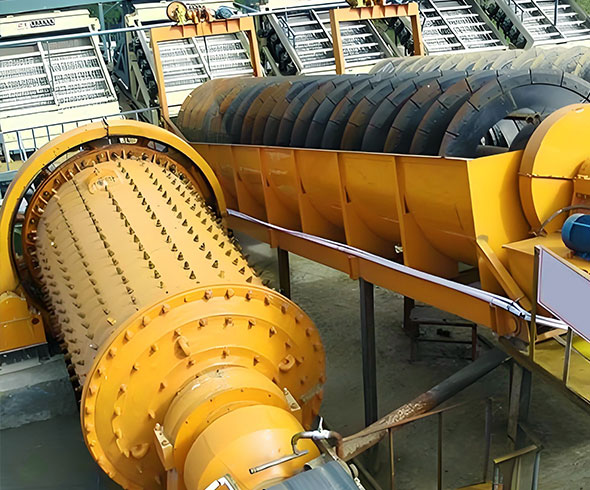

Selection and application of 100-ton ball mill

The ball mill is the key equipment for ore grinding. In mineral processing plants, it is usually combined with a classifier or hydrocyclone to complete the grinding and grading operations.The grinding effect directly affects the subsequent sorting effect and then the concentrate grade, so the correct choice of ball mill is very important.There are many types of ball mills, and the 100-ton ball mill is a key model, which is more used in the production of many large and medium-sized mines.

1. Size of 100-ton ball mill

There are many models of 100-ton ball mills, usually the diameter of the cylinder is between 2.4 meters and 3.2 meters, and the length of the cylinder is between 3 meters and 6 meters.The parameters of the cylinder diameter, length, volume (length, width and height), volume and weight of the 100-ton ball mill are listed below, which is convenient for you to choose.

2. The influence of size on the performance of a 100-ton ball mill

Different types of ball mills are listed above, and their processing capacity can reach about 100 tons, which shows the diversity of their models.However, the grinding effect of ball mills of different sizes may vary greatly. This is because size also affects the performance of ball mills. This effect is mainly manifested in the following aspects:

Cylinder length and grinding effect

The length of the cylinder has a certain impact on the grinding effect of the ball mill. This is because the length of the cylinder is long, the material stays in the mill for a long time, and the number of grinds will increase, and the particle size of the final product will be finer.If the length of the cylinder is relatively short, then the material stays in the mill for a period of time, and the particle size of the final product will be thicker.

Cylinder diameter, ball loading capacity and processing capacity

The larger the diameter of the cylinder, the larger the volume.A ball mill with a large-diameter cylinder will have a larger ball loading capacity and material loading capacity, and at the same time it will process more materials than a ball mill with a small-diameter cylinder. Therefore, the diameter of the cylinder has an impact on the ball loading capacity and processing capacity.

3. How to choose the size of the 100-ton ball mill?

There are so many models of 100-ton ball mills, and the size differences are relatively large. How do we choose?At this time, the hardness of the ore, the particle size of the feed, the requirements for the fineness of the grinding ore, and the level of energy consumption should be considered.

Ore hardness

When choosing the size of the ball mill, the hardness of the grinding material must first be considered.If the material is hard and needs to be ground for a long time, then a ball mill with a longer cylinder length must be selected.Common ores with higher hardness include quartz, orthoclase, apatite, magnetite, hematite, etc.

If the material has low hardness and is easy to grind, you can choose a ball mill with a smaller cylinder diameter and a short cylinder to reduce costs and energy consumption.For example, graphite, talc, dolomite, limestone, kaolin, etc. are all ores with lower hardness, and the Mohs hardness is between 1 and 3.

Feeding particle size

When the particle size of the feed is large, the material needs to stay in the cylinder for a long time, and the processing capacity will be reduced. At this time, a larger ball mill should be selected to extend the grinding time; when the particle size of the feed is small, you can choose a ball mill with a smaller cylinder diameter and length to improve production efficiency.

Requirements for fineness of grinding ore

The fineness requirements of the subsequent sorting process for the milled mineral products also affect the choice of size. If the fineness requirements of the mill are high and the discharge is finer, then a ball mill with a longer cylinder should be selected; if the fineness requirements of the mill are low and the milled mineral products are thicker, a short-barrel ball mill should be selected.

Energy consumption level

The energy consumption of ball mills is high and they are large energy consumers.Therefore, for ball mills with the same processing capacity, their energy-saving properties must also be considered.Although the large-size ball mill has strong processing capacity and large output, the accompanying problem is the high investment cost and high energy consumption.Although the energy consumption of a small-size ball mill is low, the output is small. How to balance the relationship between the two is also the key issue in choosing the size of a 100-ton ball mill.

4. the installation and space layout of the 100-ton ball mill

Requirements for installation space

The height of the plant should be at least 1.5~2m higher than the highest point of the ball mill, and the length should be 3~5m longer than the total length of the ball mill, while the width of the plant requires at least the total width of the ball mill (including the maintenance channel of the good policy) to be 3~5m wider.

Taking the MQG3236 ball mill as an example, its overall size is: Length×width×height=14300×6760×5200 (mm), and its weight reaches 119012kg.Then the dimensions of the plant where this billiard mill is installed are: the height is at least 6.5m, the length is at least 18m, and the width is at least 8m.

Reasonable space layout

In the grinding workshop, a reasonable space layout should meet the following conditions: ensure sufficient operating space, reasonable equipment spacing, safety of electrical equipment and coordination of auxiliary equipment.

The reasonable space layout facilitates personnel to approach the equipment for maintenance and overhaul, ensuring that the replacement of wearing parts is more convenient and fast, and at the same time, maintenance costs can be reduced and production efficiency can be improved.

5. Services that Xingmuang Group can provide

For a selection plant, the ball mill can be said to be the soul equipment of the entire selection plant. It is responsible for important grinding operations and also undertakes subsequent processes.Xingkuang Group understands the importance of ball mills, so we have been continuously improving our equipment for many years. After many upgrades and retrofits, our ball mills are now capable of grinding more than 70 kinds of minerals, which can adapt to various harsh environments, with higher grinding efficiency and stronger production capacity.

Xingkuang Group's mining equipment has an experienced and highly skilled professional team, which can help customers complete one-stop services such as equipment selection, on-site installation, commissioning and operation, commissioning and commissioning, and worker training.By choosing Xingmuang Group, you will get efficient, stable and economical mining production solutions to create greater value for your business.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China