Industry news

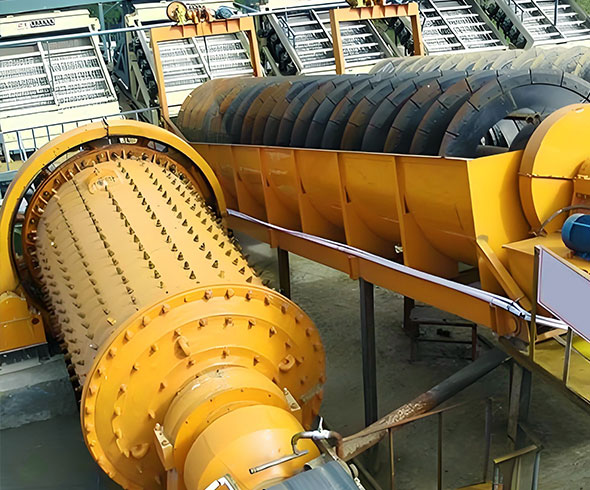

How to choose a ball mill for different types of iron ore?

Ball mills play a role in grinding small pieces of iron ore into small particles when processing iron ore. The particle size of the ground ore product is usually required to be 60%~95% of 200 mesh.The choice of ball mill type varies greatly depending on the particle size of the product.This article will analyze the selection of iron ore ball mills from four different types of hematite, magnetite, limonite and siderite.

Hematite ball mill

Hematite is a kind of iron oxide, containing about 70% iron ore, generally has a hardness of 5~6, and is red to light gray on the outside, sometimes black or dark red with stripes.For this type of iron ore, when processing ore, a lattice ball mill is generally selected as the first stage of grinding, and an overflow ball mill is used as the second stage of grinding.

Magnetite ball mill

Magnetite is also a kind of oxidized iron ore. The iron ore content is generally about 72%. The appearance is black-gray with metallic luster and black streaks. It is commonly known as “green ore”. Magnetite is generally very hard.In mineral processing plants, depending on the nature of magnetite ore and the scale of treatment, generally one stage of grinding will use an energy-saving lattice ball mill, so that its fineness reaches 200 mesh accounting for 67%, and with spiral grading to form a grinding grading system, the second stage of grinding uses a conical overflow ball mill, and a cyclone to form a grinding grading system, at the same time, a fine sieve will be used to strictly control the grading particle size.

Limonite ball mill

Limonite is a kind of iron trioxide containing crystallized water. It is a general term for two different structural ores, goethite and phosphorite. Its iron content is 37% to 55%. Some limonite has a higher phosphorus content, which is more difficult to select.For this type of ore, a three-stage grinding process is often used. The first stage is a lattice ball mill with a grinding fineness of 200 accounting for 60%, and the second and third stages are overflow ball mills with a grinding particle size of 200 mesh accounting for 87% and 325 mesh accounting for 95%, respectively.

Rhombite ball mill

The composition of rhombite is mainly ferrous carbonate, the iron content is generally 48.2%, the color is generally gray-white or yellow-white, and it can become brown or brownish-black after weathering. It is a hard and dense rhombite.This type of iron ore often adopts the magnetic separation process of the stage grinding stage. One stage of the grinding adopts a lattice ball mill, the second stage of the grinding adopts an energy-saving overflow ball mill, and the third stage of the grinding can use an overflow ball mill or a conical overflow ball mill, depending on the nature of the rhombite ore and the particle size requirements of the grinding.

No matter what kind of iron ore it is, we should pay attention to the selection of ball mill specifications and models. Choosing suitable grinding equipment can improve the work efficiency of iron ore processing plants and promote the recovery rate of mineral processing and the improvement of concentrate grade.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0086 138 3714 0277

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China