Industry news

Dehydration equipment commonly used in the mineral processing industry

After the minerals are sorted by reselection, flotation, magnetic separation and other processes, the concentrate and tailings contain a lot of water.In mineral processing plants, the dehydration of tailings is very important. After the tailings are dehydrated, it can not only save the cost of building the tailings reservoir, reduce the safety risks of the tailings reservoir, and reuse the backwater.The concentrate, on the other hand, needs to be dehydrated because it is sent to the smelter for smelting.

In the dewatering operations of mineral processing plants, the dewatering equipment commonly used is a thickener, a filter and a dewatering screen.

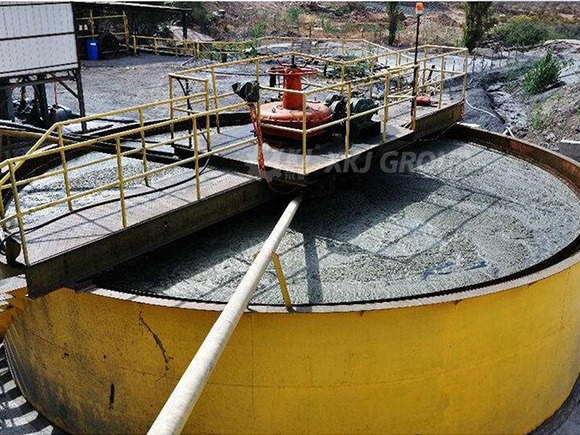

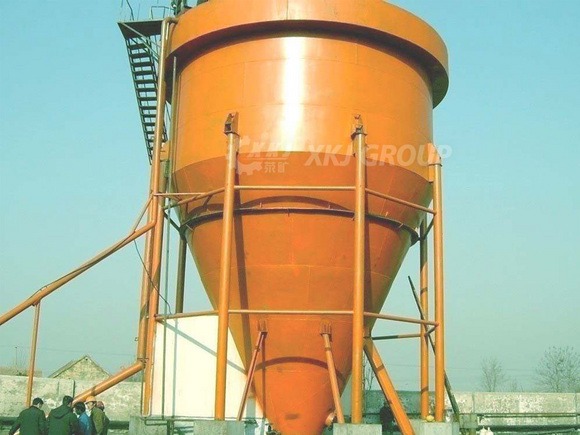

The solid particles in the thickener precipitate to the bottom of the pool due to gravity, and are further concentrated under the action of a scraper, and finally discharged from the discharge port, while the upper water is discharged from the overflow tank.The thickener is generally used for the initial concentration of concentrate or the dehydration of tailings. When the thickener is used for concentrate concentration, the bottom flow concentration is generally below 75%. In order to prevent the loss of concentrate, the overflow concentration of the thickener must also be controlled to a certain extent; when the thickener is used for tailings dehydration, the concentration after concentration is generally 65%, and the solid content of the overflow is less than 0.5%.

In mineral processing plants, continuous concentrators are usually used, that is, the slurry is continuously transported to the concentrator, and the overflow water and the discharge of concentrated products are continuously produced.According to its transmission method, the thickener can be divided into two types: central transmission type and peripheral transmission type.

A filter is a dehydration device used to further remove moisture from a concentrated product.According to the different power sources, the filters can be divided into gravity filters, pressurized filters, vacuum filters and centrifugal filters. In most cases, vacuum filters are used in selected factories.The vacuum filter uses the suction of the pump to form a pressure difference on both sides of the filter cloth, so that the slurry passes through the filter cloth to become a filtrate, and the solid particles remain on the filter cloth to become a filter cake, and then scraped off with a scraper. The filtration work is carried out continuously.

The production capacity of the vacuum filter is low and is not suitable for the needs of production development.In recent years, a new type of filtration equipment has emerged—a vacuum permanent magnet filter. Its structure is similar to a cylindrical vacuum filter, except that a permanent magnet magnetic system is installed inside the cylinder to quickly attract magnetic minerals to the surface of the filter cloth.The filter is mainly suitable for dehydration of coarse-grained ferromagnetic concentrate slurry.

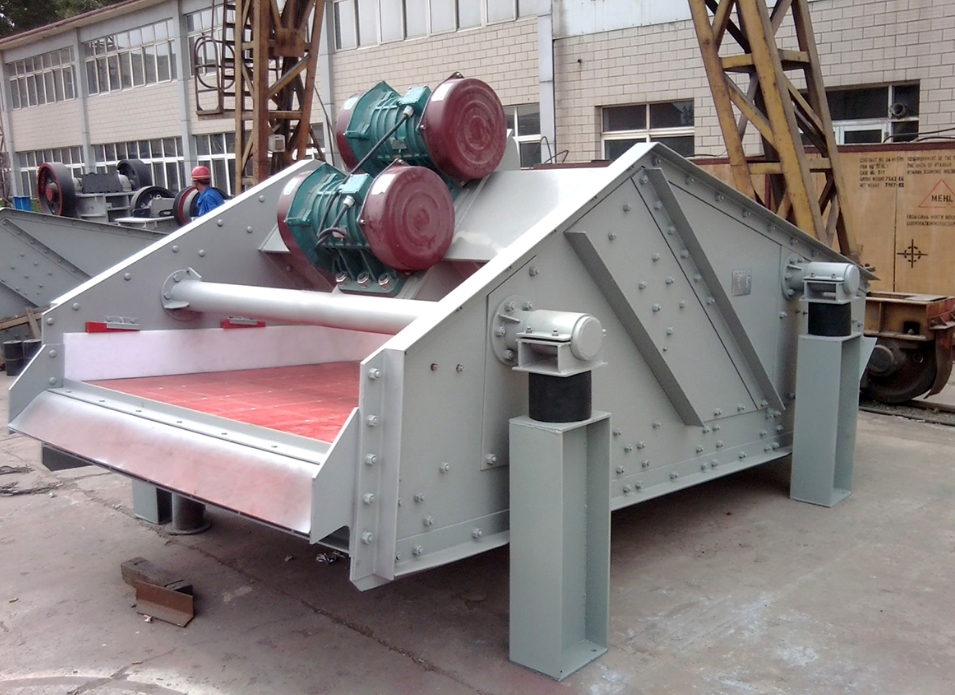

Dewatering screen is a kind of high-efficiency dewatering equipment, mainly used in tailings dry discharge, concentrate dewatering, carbon slurry separation and other operations, with a wide range of adaptability, sufficient dewatering and other advantages.

The above are the dehydration equipment commonly used in the mineral processing industry. If you happen to be interested in dehydration equipment, please contact us.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China