Industry news

Bauxite mill has good vertical grinding effect

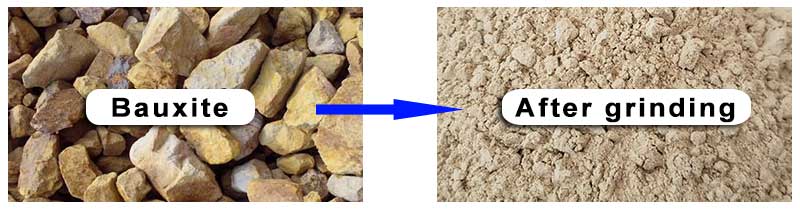

Bauxite, also known as bauxite or bauxite, is a soil-like mineral. The main component is alumina, which is hydrated alumina containing impurities. After grinding, it is commonly used in aviation, automobiles, electrical appliances, chemical industry, cement, abrasive materials, ceramics and other industrial fields. What equipment is good for bauxite grinding?How much is the price?

What equipment is good for bauxite grinding?

Bauxite is a general term for ores composed of aluminite trihydrate and aluminite monohydrate as the main minerals. It often has oolitic, bean-like structure, and bulk structure. It has a mohs hardness of 2.5-3.5 and a density of 3.9-4 g/CM3. There are many types of mill equipment on the market. Considering the characteristics of the materials, it is better to choose Raymond mills and ultrafine mills.

Raymond Mill

Daily output of 8-176 tons

Feed particle size: ≤30mm

Finished product particle size: 0.173-0.044mm

It is made by updating and improving the design, with a three-dimensional structure design and a small footprint. It is an independent production system from the block material to the finished powder. It is complete and cost-saving. Through the combined action of the analysis machine and the fan, it can meet the requirements of different users. The finished fine powder has good quality, uniformity, high sorting accuracy, and fineness can be adjusted according to demand. The main transmission device adopts a closed gearbox and pulley, and the transmission is stable. The electrical system adopts centralized control, which can basically realize unmanned operation and improve operating efficiency.

Ultrafine vertical mill

Output 0.4-40 tons per hour

Feed particle size: <40mm

Finished product particle size: 0.25-0.015mm

According to the actual situation of users using grinding equipment over the years, and in view of the needs of the development of the grinding industry, a new type of high-tech product has been painstakingly developed. The internal structure and main components have been improved, and the grinding roller linkage booster technology has made the operation more stable, the milling pressure is large, and the output is significantly increased. The spring booster device increases the grinding force. The powder separator adopts a low-resistance hanging cage powder separator, which has high sorting efficiency and adapts to the needs of different fineness. The special steel frame supports the analysis machine, and the equipment runs smoothly. At the same time, it is equipped with a special pulse dust collector, which has a high dust removal effect and basically realizes dust-free operation in the workshop.

Bauxite mill customer site

Project location: Indonesia

Feed particle size: <25mm

Processing capacity: 0.8-10t/h

Bauxite grinding process flow: raw materials → jaw crusher → bucket elevator → electromagnetic vibration feeder→ Raymond mill→ powder separator → dust collector → finished product;

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China